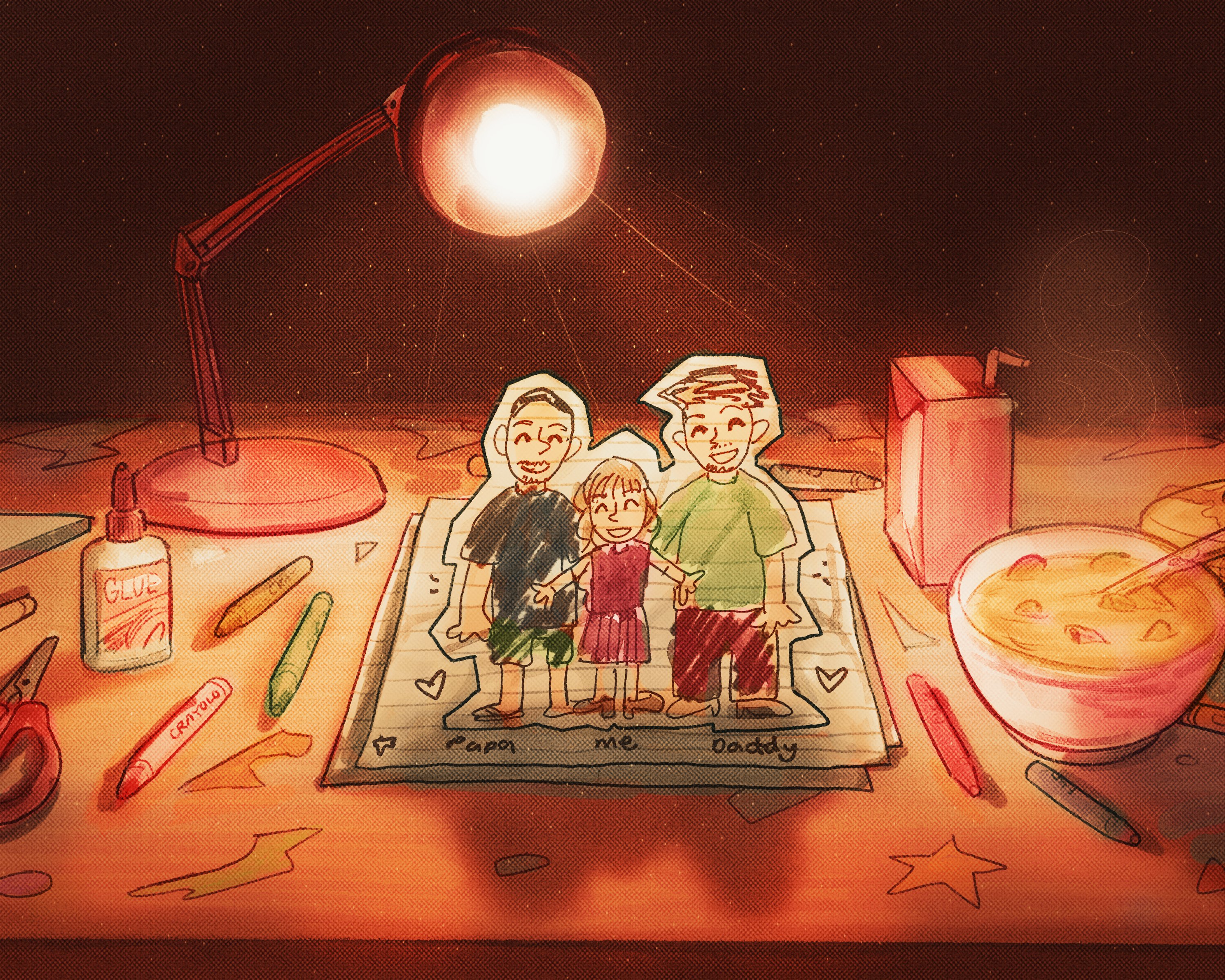

Chemical engineering student RC, not their real name, will finally wear their sablay tomorrow in the university graduation after a long journey capped by their thesis. Yet the completion of this last requirement was marked by struggles spanning across semesters, most of which were constituted by procurement and financial woes.

“Midyear pa lang nag-procure na kami para at least [makatapos] sa second sem,” they said.

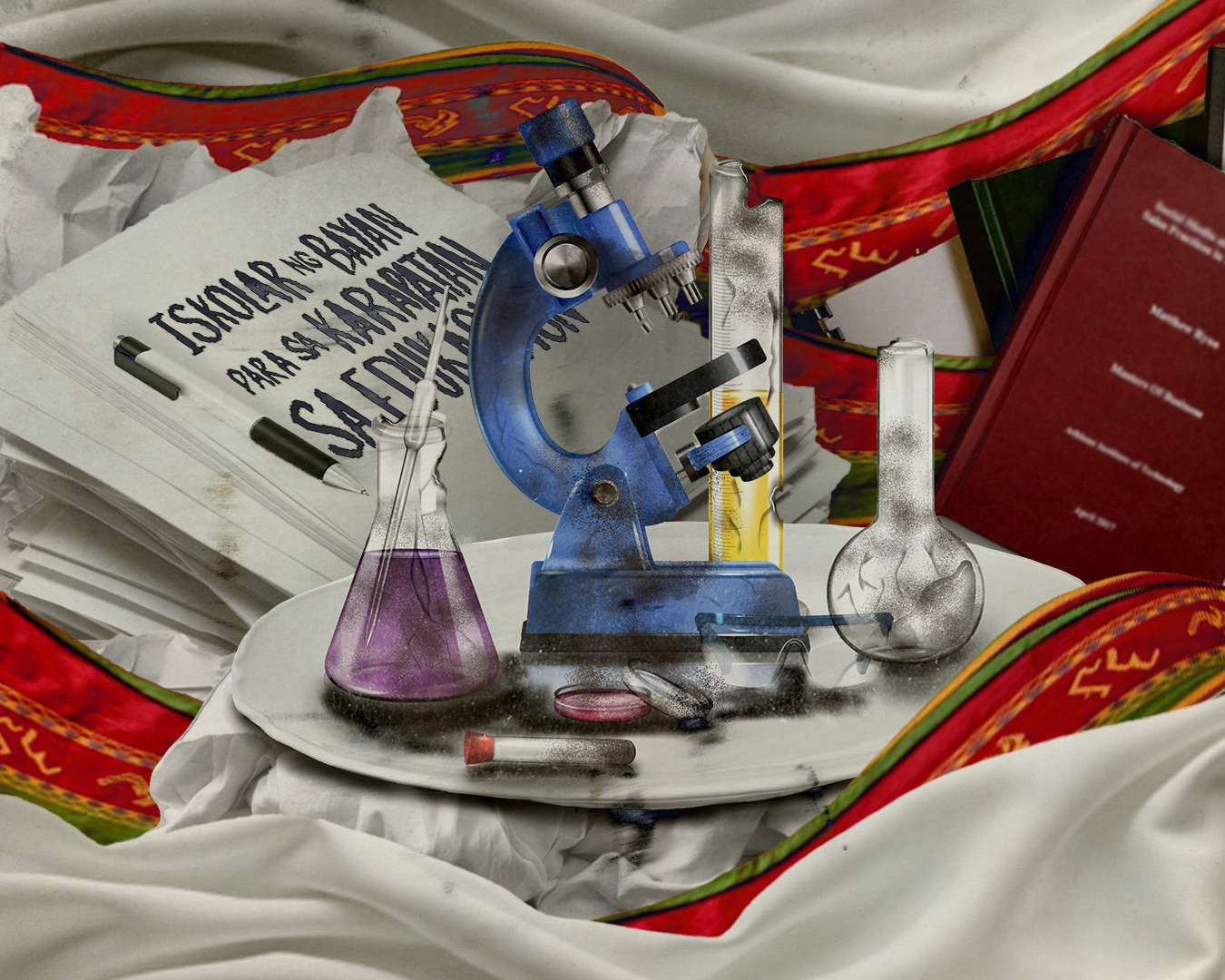

For most students, their thesis acts as the last throes of their undergraduate life. They must contend with the challenges posed by economic constraints and a procurement law that hinders the university’s timely acquisition of quality materials and equipment, risking their research outcome and academic standing.

Research Costs

RC’s thesis planning started in one of the wet laboratories on the campus near the end of their third year. They had to create tangible prototypes for their group’s attempt to integrate new materials to clean wastewater alongside carbon fiber filters.

Their research funding was a mix of grants from the Department of Science and Technology and the College of Engineering. Excess funds from their thesis adviser also covered most of RC’s group’s fees. Despite that, they still had out-of-pocket expenses of more than P30,000 later in their fourth year.

To maximize their limited fund, their group spent two months contacting vendors of lab-grade equipment and chemicals, seeking the lowest prices available. Under the Government Procurement Reform Act, an immediate procurement method for goods costing less than P200,000 requires at least three price quotations, the lowest of which would be awarded the contract.

Some chemicals were sourced locally, but international suppliers had to go through regulatory bodies for certain shipments. They only received the materials two months after ordering, but some arrived even later.

After RC and their group created filters in the first semester using the materials they waited so long to procure, they had to scour accessible facilities to test their prototypes. The closure of their department’s building and the absence of some expensive equipment in the university also narrowed down their list of facilities, leading them to opt for outside testing.

“Ito yung kailangan din ng funding kasi medyo mahal siya and dependent sya sa number of prototypes or items na itetest. So mayroon kami I think 4 or 5 [different] tests,” RC said.

These included the use of a muffle furnace from Adamson University and a thermogravimetric analyzer from the University of Santo Tomas. The group paid P9,000 in testing fees for just two pieces of equipment alone.

Such is a shared struggle for prototype-heavy research in the university. JR, not his real name and a former Natural Sciences Research Institute research assistant, worked on a project under the institute in 2023. There, he witnessed students and colleagues go to De La Salle University for testing, as the use of the scanning electron microscope (SEM) at UP was costlier.

“So P5,000 yung sa DMMME tapos nakahanap namin na mas mura pala yung presyo ng analysis namin for SEM sa DLSU. So imbes na makapag-analysis kami na malapit-malapitan lang sa UP lang, ang nangyayari is hindi namin magawa yun kasi mas mahal yung quotes,” JR said.

Review of Related Laws

Equipment costs, however, are only one horn of the problem. Because of procedural problems, access to rare equipment becomes elusive, too.

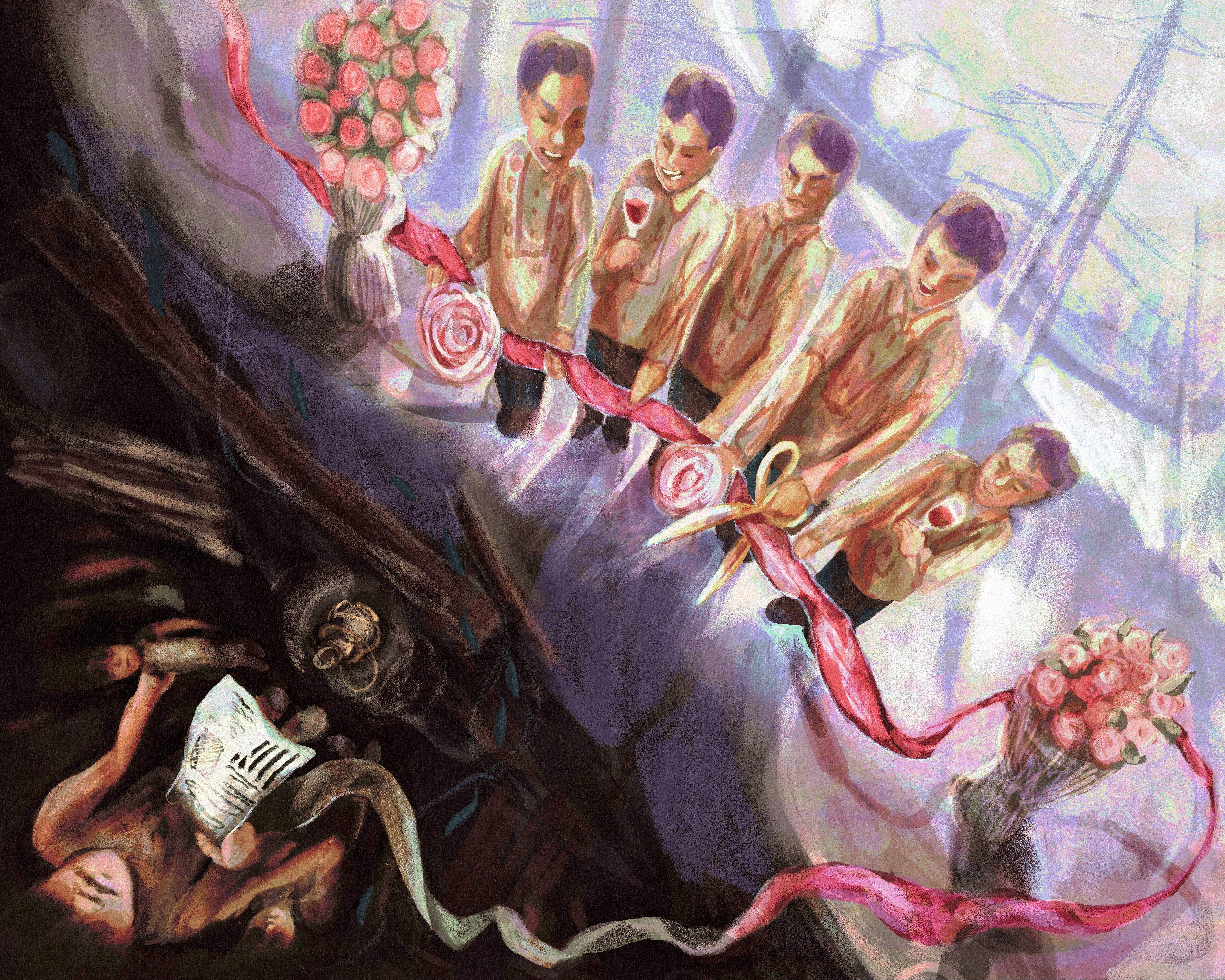

College of Science Dean Giovanni Tapang outlined the problems faced by senior faculty in a Senate hearing on the old procurement law. Some international suppliers were unwilling to register in the Philippine Government Electronic Procurement System. Scientists can only access these materials when local suppliers buy them, which often makes them more expensive.

Research outputs thus get delayed as materials go through a labyrinthine process before even making it to the laboratory. A tedious bidding procedure must first be concluded before having to wait for the already long shipment times. Part of such a procedure is the awarding of a contract to the bid with the lowest calculated price.

As such, there were cases where the price per gram of specific chemicals was cheaper, but since they cost more in terms of wholesale prices, laboratories opted for smaller quantities despite not being the most economical choice, shared JR.

Those were the aspects that the New Government Procurement Act (NGPA) improved on, passed in July 2024. The NGPA forgoes the lowest calculated bid requirement of the old iteration of the law, supplanted by the Most Economically Advantageous Responsive Bid principle, which takes into account the quality of the procured material and other costs of its maintenance as well.

Section 32 of the law also introduces direct acquisition, which permits direct procurement for goods costing less than P200,000. This allows researchers to bypass some of the added bureaucratic layers, possibly reducing their economic burdens and waiting time. Whether this is to be realized would be determined in the coming years to come of its implementation.

Conclusion and Recommendations

Changes in the procurement forms only a part of a larger solution to easing the burdens of students and researchers in the university. A prerequisite for procurement, after all, is the availability of funds, especially for those who are accomplishing their thesis requirements.

“Paglaanan ng funds yung equipment not just for experiments but for testings kasi ang daming opportunities sana na mababawasan sa expenses ng students, kahit ng labs kung meron tayong equipment,” said RC.

Such a call becomes more pressing after UP this year just suffered its largest budget cut in at least 20 years. Beyond lobbying for procurement changes, university officials must also advocate for their students and researchers by demanding sufficient financing that covers the needs of all constituents.

Graduation may come for RC, but their experiences remain a telltale to the struggles of students in a university that prides itself on research output. No one should fear getting delayed trying to hurdle through bureaucratic and economic constraints, from procurement challenges to inconvenient testing facilities beyond the campus. ●

First published in the July 5, 2025 print issue of the Collegian.